Orchestrating the Perfect Performance: A Stage Manufacturer's Guide to Concert Stage Production

The roar of the crowd, the dazzling lights, the electrifying music - these are the hallmarks of a successful concert. Behind the scenes, however, lies the meticulous work of a stage manufacturer, orchestrating the physical foundation for this captivating spectacle. Building a concert stage is an intricate process that demands collaboration, creativity, and a deep understanding of the client's vision.

1. Unveiling the Stage Design: A Symphony of Choices

The journey begins with the client's vision. As a stage manufacturer, we are not simply builders but collaborators, helping artists and event organizers translate their creative dreams into tangible reality. This starts with a comprehensive understanding of the concert's concept, target audience, and performance requirements.

We present a range of stage design options tailored to their needs, encompassing various styles, sizes, and configurations. From the classic rectangular platform to multi-level structures with intricate lighting and sound integration, we offer a diverse palette of possibilities. This initial consultation serves as a brainstorming session, allowing the client to visualize potential stage layouts and explore different aesthetic directions.

2. Dimensioning the Dream: A Balance of Aesthetics and Functionality

Once the client has chosen a design, the stage manufacturer moves into the critical stage of dimensioning. This involves translating the design into precise measurements, taking into account factors such as the performance space, audience capacity, and technical requirements.

Our expertise lies in balancing the client's artistic vision with practical considerations. We suggest optimal dimensions that ensure optimal visibility, sound projection, and artist comfort while remaining within budget constraints. This collaborative process fosters transparency and trust, ensuring the client's satisfaction throughout the entire construction process.

3. Budget Breakdown: A Transparent Roadmap to Completion

With the stage design and dimensions finalized, we create a Bill of Quantities (BOQ). This detailed document outlines all the materials, components, labor, and services needed for the stage construction.

The BOQ is presented to the client, providing a comprehensive breakdown of costs and a clear understanding of the project's scope. This transparent approach allows for open communication, addressing any queries or adjustments the client may have. It also ensures that there are no surprises regarding the final costs, fostering a strong foundation of trust and collaboration.

4. Down Payment and Draft Design: Solidifying the Vision

For large-scale concert stages, a down payment is typically required to initiate the production process. This secures the manufacturing resources and ensures the client's commitment to the project.

Following the down payment, the stage manufacturer develops a detailed draft design. This includes technical drawings, material specifications, and structural plans, providing a visual representation of the final stage. This step allows for further client review and refinement, ensuring that the final product aligns perfectly with their vision.

5. Sampling and Mass Production: Perfecting the Details

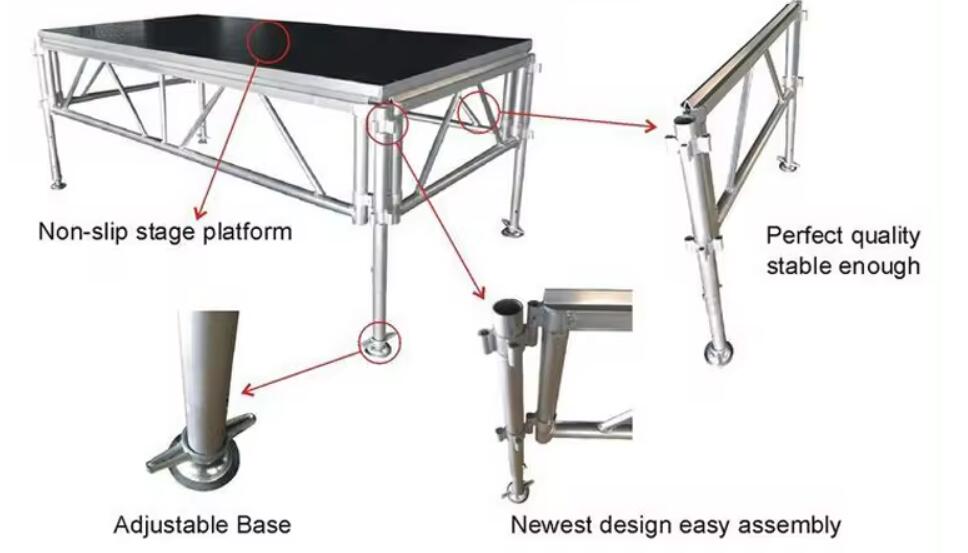

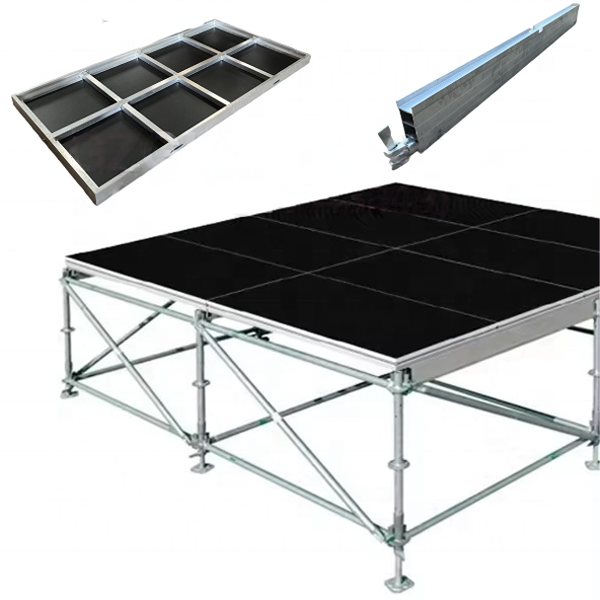

To ensure the highest quality and meet the client's specific requirements, we undertake a meticulous sampling process. This involves creating custom-made individual components, such as stage flooring panels, riser sections, or unique lighting fixtures. These samples are thoroughly tested for durability, functionality, and aesthetic integrity.

After passing these rigorous checks, we proceed with mass production. The entire stage is meticulously assembled, adhering to the approved draft design and ensuring consistency in materials and construction quality.

6. Factory Production and Trial Installation: A Symphony in Action

The final stage of the process takes place within the manufacturer's facility. Here, the stage is assembled and subjected to a comprehensive trial installation. This rigorous testing simulates real-world performance conditions, ensuring that all components seamlessly integrate and function flawlessly.

From checking the structural integrity to testing lighting and sound systems, this trial installation is a critical step in guaranteeing a flawless performance on the actual stage. Any necessary adjustments are made at this stage, ensuring a polished and professional finish before delivery.

Conclusion: A Stage for Success

The production of a concert stage is a complex endeavor requiring collaboration, precision, and a dedication to excellence. By adhering to these key steps, a stage manufacturer can ensure the delivery of a high-quality stage that meets the client's vision and enhances the overall concert experience. From concept to completion, the process is an intricate symphony of creativity, technical expertise, and meticulous craftsmanship, ultimately resulting in a platform for unforgettable performances and lasting memories.